The repAS-25 repetitive injector is used for multiple injections of samples from a storage vessel.

The sample volume, feed speed and other parameters can be set, and the injection sequence is controlled from the control software used, e.g. PrepCon.

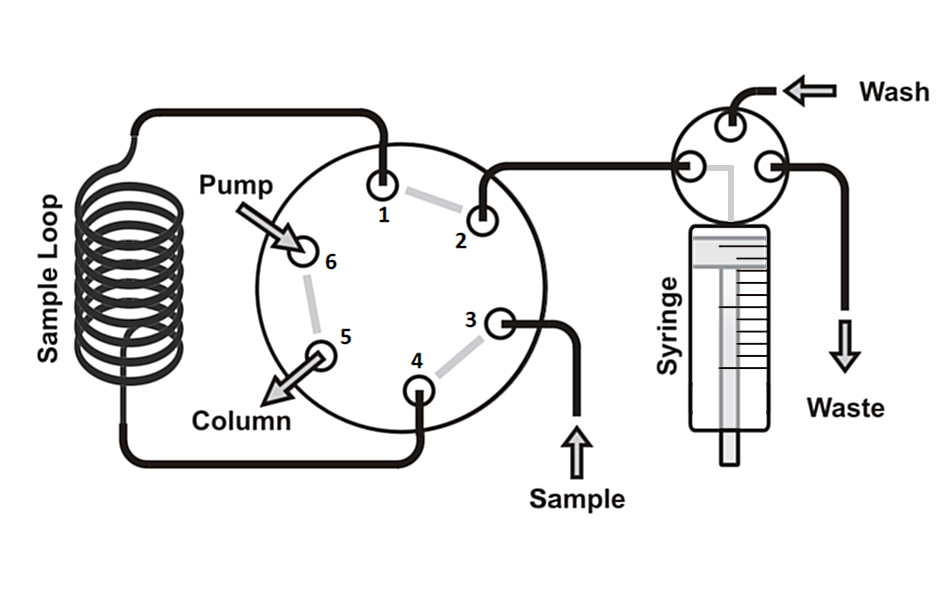

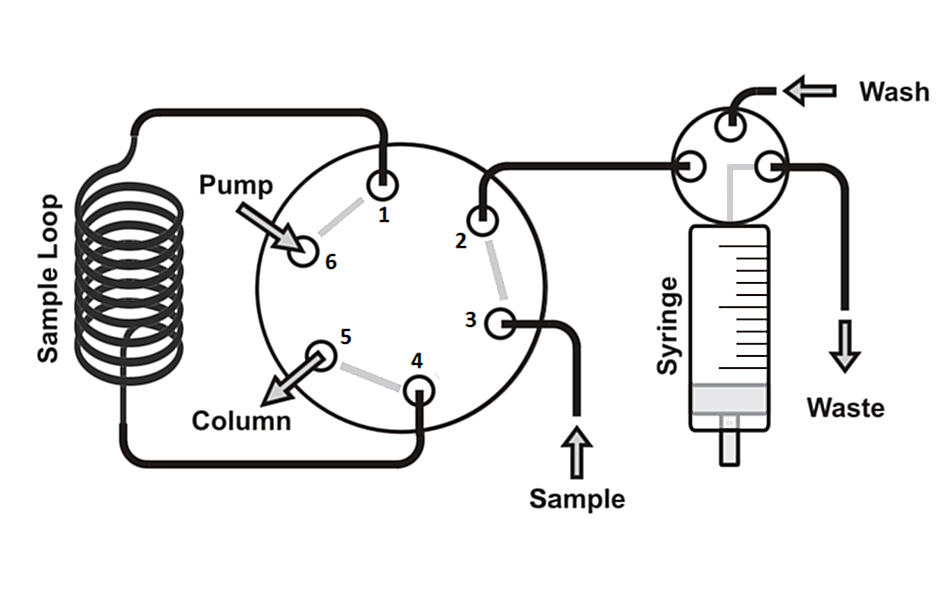

Injector operation

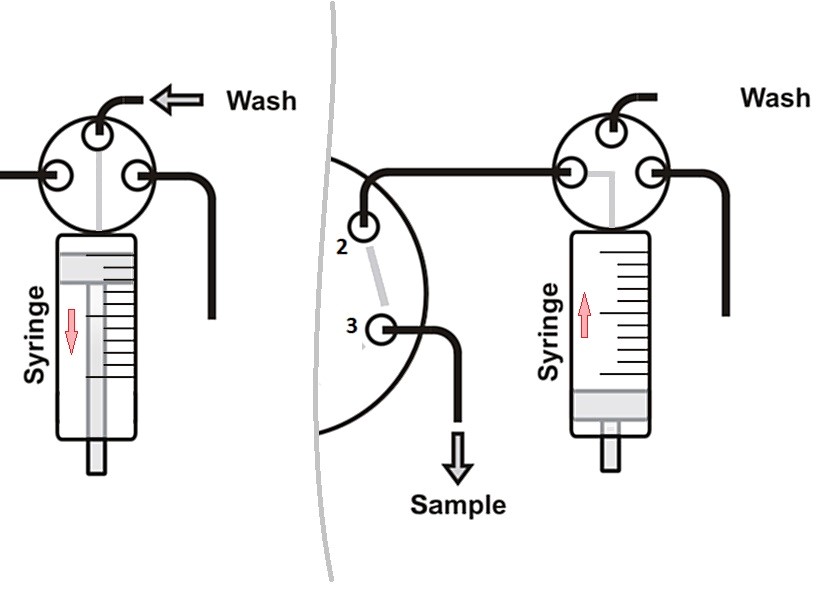

- Load the sample: The injection valve and the syringe valve are in the position shown in the “Load” figure. When the syringe plunger is moved down, sample is drawn from the sample reservoir into the sample loop.

- Unloading the syringe: If the syringe valve is set to the position shown in the “Inject” figure, the syringe can be emptied into the waste container by raising the piston. If the sample loop does not yet contain the desired amount of sample, the 1st step (loading sample) can now be repeated.

- Inject: If the injection valve is set to the position shown in the figure “Inject”, the contents of the sample loop are transported from the eluent into the separation column. In the arrangement shown, the sample loop is emptied in the opposite direction compared to filling. Therefore, smaller sample volumes than the volume of the sample loop can also be injected without carryover.

- Flushing the sample aspiration line: As shown in the “Flushing” figure, flushing liquid can be aspirated via the center position of the syringe valve and expelled via the sample aspiration line.

| Maximum volume per injection | corresponds to sample loop volume |

| Injection valve | Knauer VU4.1 with 6-Port 2-Position |

| Connections | Pipe fittings1/8″ oder 1/16″ |

| Syringe drive | Dispenser Cavro XC (Syringe sizes available from 50µl to 5ml) |

| Wetted materials | Stainless steelDIN 1.4571, FEP, KEL-F, PTFE, Glas |

| Dimensions | 17 x 30 x 30 cm without sample loop and aspiration needle |

| Weight | 7 kg |

| Communication | Ethernet |

| Power consumption | up to 125 W |

| Power supply | 230 V AC |