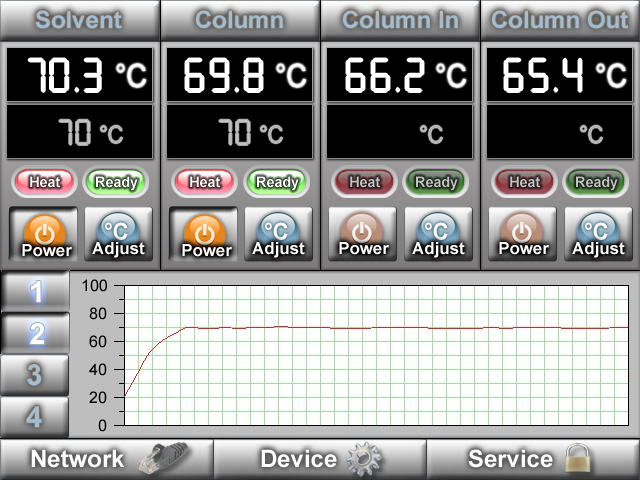

Device for precise and stable temperature control of eluents for preparative chromatography

- Stainless steel DIN 1.4404

- Maximum flow rate: 300 ml/min

- Maximum operating pressure: 400 bar

- Temperature range: RT – 100 °C

- Dead-Volume: ca. 6.5 ml

- Heating Power: 1000 W

- Connections for heating sleeves

Standard equipment:

2 x Heating e.g. eluent heater + column heating jacket

2 x Temperature measurement

Special equipment:

Maximum 8 x heating control or temperature measurement

Temperature settings and display:

Manually via touch screen

Via network or RS-232

Via software: PrepCon or SCPA Templogger

Sensors: Pt100

Control accuracy: typical +0.5%

Calibration of all temperature sensors and heating controllers by the end user possible

| Temperature control range | Room temperature (RT) bis 100°C |

| Heating power | 1000 W |

| Heating distance | 6.5 Meter Stainless steel capillary |

| Flowrate | up to approx. 300 ml/min |

| Capillaries | 1/16″ mit 1.0 mm Inner diameter |

| Capillary connection | UNF 10-32 Female thread |

| Dead volume | approx. 4.5 ml |

| Wetted materials | Stainless steel DIN 1.4404 | AISI/SAE 316L (Titanium possible on request) |

| System protection | Thermal insulation, temperature protection switch (110°C) |

| Dimensions (H x B x T) | 18 x 30 x 28 cm (34 cm with connectors) |

| Weight | 13 kg |

| Temperature acquisition | Pt100 Resistance thermometer |

| Channels | Any combination of up to 8 control and display channels possible, maximum 4 operable via touch screen |

| Communication | Ethernet or RS-232 (Serial) |

| Power consumption | 1050 W |

| Power supply | 230 V AC |